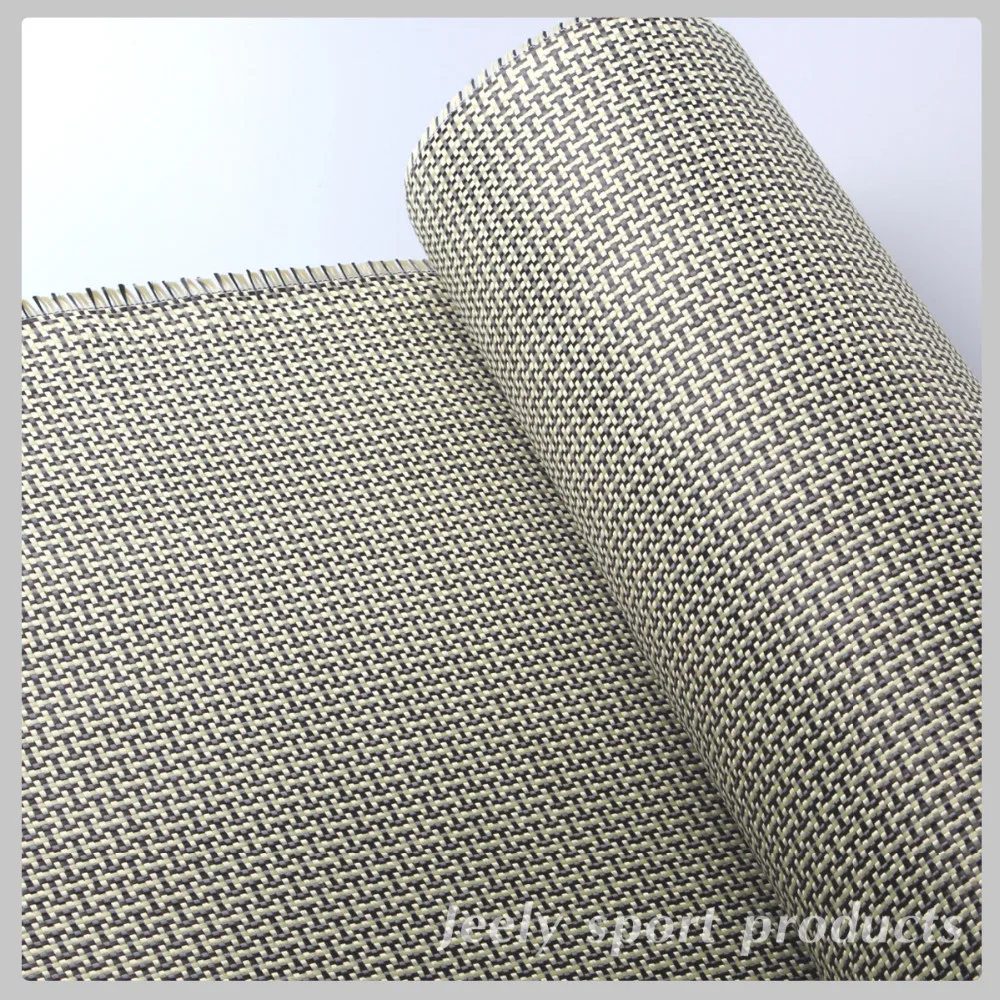

I'm thinking it might be a way for me to try one of these fancy carbon-arylate blades. They're generally way too heavy for what I like, being around 90 grams. If I can shave 10g off I'd be able to use it. Problem is... the heat might affect the epoxy they use in the cloth layup. Epoxy creeps when it gets hot. I'd perhaps have to build some sort of press to keep the layers from coming apart and use a fairly low temperature over a longer period of time. Naah…

Iskandar